Omniverse for Automation Simulation

Automotive

Robotics

Synthetic Data

Our automotive customer needed to automate the movement of cars coming off the production line to various stations in the factory.

| Differential Drive | Omnidirectional Drive | Ackermann Steering |

|---|---|---|

|

|

|

Various robots and even tele-operation solutions exist, but exploring them all with pilot projects would have taken too long, been too costly and it would have disrupted the production line.

Simpler scenario calculations did not answer the really important questions:

- How many robots do we need to cover all shifts and all stations?

- How do the robots behave in a realistic environment, including limited space, limited battery life, and other traffic?

- How can we adapt our factory layout to optimize the flow of robots and cars? How does this change the number and type of robots we need?

Approach

We built a simulation environment in NVIDIA's Isaac Sim to answer these questions, and to simulate the behavior of different types of autonomous mobile robots (AMRs) in a factory setting.

Using the library of open source robot models for ROS and synthetic data generation capabilities of Omniverse, the Motius team put together realistic simulations of each robot type, and the factory environment.

Software Architecture

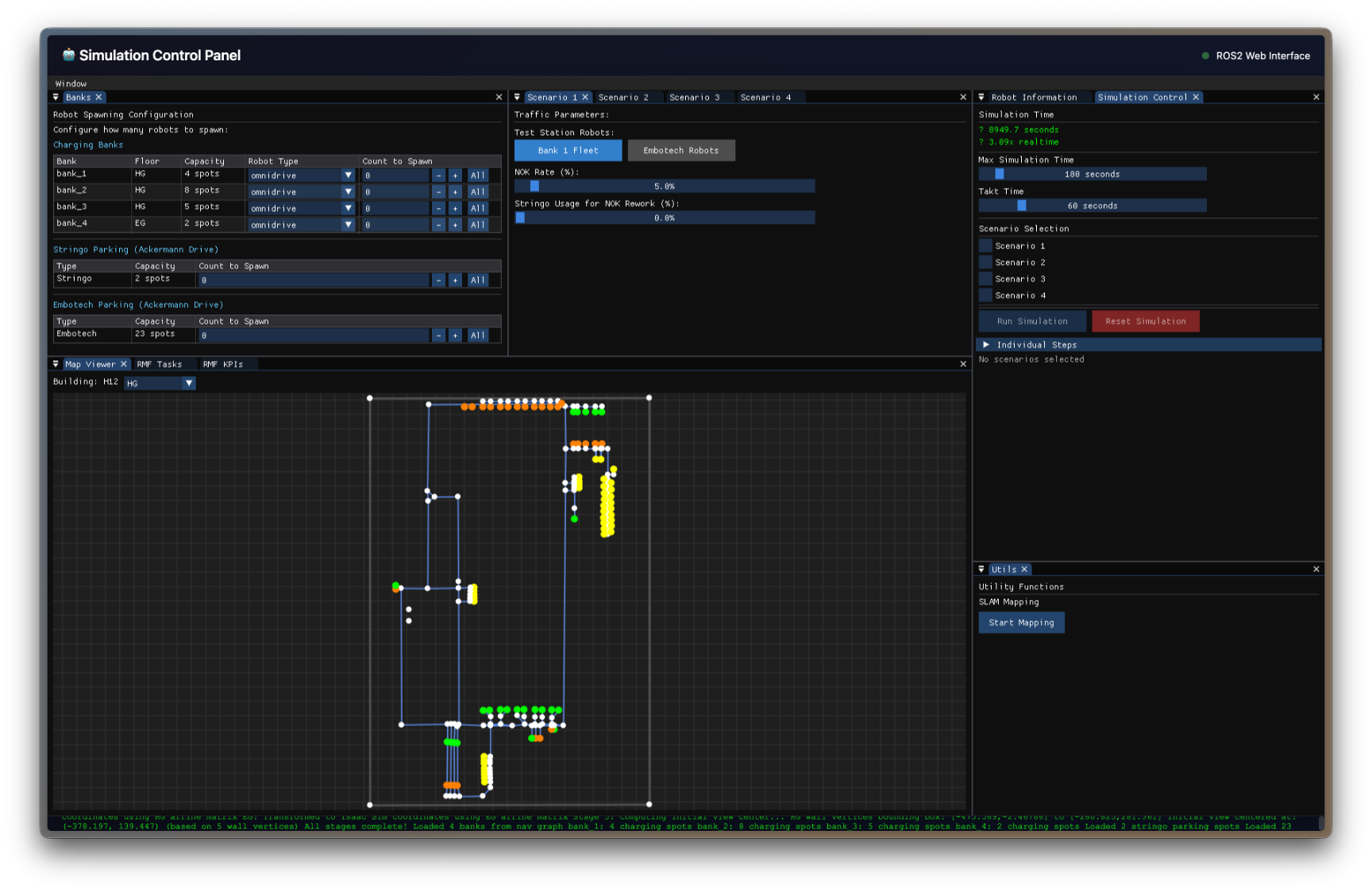

Next to Isaac Sim, we needed a central fleet manager to realistically control the robots. The scenarios also needed to be controlled and monitored.

-

Isaac Sim Environment

The simulation environment is built using NVIDIA's Isaac Sim, which provides a realistic physics engine and rendering capabilities for simulating autonomous mobile robots (AMRs) in a factory setting.

-

Integration Points

OpenRMF integrates with the simulation environment to send commands, create robots dynamically, and provide real-time feedback on robot poses.

Finally, results of the simulation (robot types, number, performance, etc.) needed to be logged and analyzed.

graph TD

subgraph "Isaac Sim Environment"

Workspace[Factory Workspace Model]

subgraph AMR["AMR Abstractions"]

DiffDrive[Diff Drive AMR]

Ackermann[Ackermann AMR]

OmniDrive[Omni Drive AMR]

end

subgraph "ROS2 Bridge"

CmdSub[Command Subscribers]

TFPub[TF Publishers]

end

subgraph "Custom Bridge"

RobotCreator[Robot Creator Service]

Spawner[Robot Spawner]

end

end

subgraph "External Components"

ImGUI["ImGUI Interface"]

OpenRMF[OpenRMF Commands]

ROS2Nodes[External ROS2 Nodes]

end

ROS2Nodes --> CmdSub

TFPub --> ROS2Nodes

OpenRMF --> ROS2Nodes

RobotCreator --> Spawner

Spawner --> DiffDrive

Spawner --> Ackermann

Spawner --> OmniDrive

ImGUI --> RobotCreator

CmdSub --> AMR

AMR --> TFPubOpenRMF

Demo video of Open RMF in a multi-story office building

OpenRMF is used as a fleet management system and central map server:

- Each robot gets its own Zenoh bridge for isolated control

- Traffic Management prevents AMRs from crashing into each other using the building map and tracks where each robot is going

- Web dashboard lets operators the status of the robot and task execution

- We built tools to import maps and define zones of interest

OpenRMF Architecture

graph TD

ZenohRouter["Zenoh Communication Router<br/>Data routing & discovery"]

subgraph Robots["Robots"]

ZenohBridge1["Zenoh to ROS2 Bridge<br/>robot_1"]

ZenohBridge2["Zenoh to ROS2 Bridge<br/>robot_2"]

end

subgraph OpenRMF["OpenRMF"]

TrafficSchedule["Traffic Scheduling Service<br/>Collision avoidance & flow optimization"]

FleetAdapter["Fleet Adapter Service<br/>Robot command & status interface"]

Dashboard["Fleet Management Dashboard<br/>Web UI for monitoring & control"]

APIServer["API Server<br/>REST & WebSocket APIs"]

TrajectoryViz["Trajectory Visualization Service<br/>Real-time path monitoring"]

MapServer["Building Map Server<br/>Spatial data & navigation maps"]

end

ZenohRouter --> ZenohBridge1

ZenohRouter --> ZenohBridge2

Robots ---> TrafficSchedule

Robots --> FleetAdapter

MapServer --> TrafficSchedule

TrafficSchedule --> APIServer

FleetAdapter --> APIServer

APIServer --> Dashboard

APIServer --> TrajectoryVizControl Plane

Development Workflow

- Our simulation runs in a Kubernetes cluster, allowing us to develop and test scenarios locally or in the cloud.

- Bazel is used to manage dependencies and build the simulation environment, ensuring a consistent and reproducible development workflow.

Structure in Bazel

graph TD

subgraph "Bazel Module"

subgraph Core[Core Applications]

TeleopApp[Teleop App]

subgraph "ImGUI Application"

ImGUIApp[ImGUI App]

end

subgraph "Simulation Scenarios"

ScenarioManager[Scenario Manager]

ParamHandlers[Simulation Parameters]

end

DispatchLogic[Scenario Dispatch Logic]

end

subgraph "Communication Layer"

ZenohBridge[Zenoh-ROS2 Bridge]

MsgPkg[ROS2 Messages & Services Package]

end

subgraph "Hardware Simulation"

BatterySim[Battery System Simulation]

HWSims[Other Hardware Simulations]

end

end

subgraph External[External Systems]

FleetManager[Fleet Manager]

IsaacSim[Isaac Sim Environment]

Xpra[Xpra Streaming Server]

end

ImGUIApp --> ParamHandlers

ImGUIApp --> DispatchLogic

ParamHandlers --> ScenarioManager

DispatchLogic --> ScenarioManager

ImGUIApp --> Xpra

TeleopApp --> IsaacSim

Core -- External

DispatchLogic -->FleetManager

DispatchLogic --> IsaacSim

ZenohBridge <--> IsaacSim

BatterySim <--> ZenohBridge

HWSims --> ZenohBridgeDeployment

Our simulation runs in Kubernetes, both locally for engineering, and in a cloud environment for executing long-running scenarios.

The cloud deployment comes with external systems that allow remote access, tracking KPIs of the scenarios, and tracing simulation execution.

Application at Keller & Kalmbach

Using the Omniverse simulation environment, Keller & Kalmbach can now:

- Simulate automation scenarios with mobile & stationary robots, at 80% accuracy in only 20% of the time it would take to pilot them

- Test real software components in a physics-based simulation environment

- Easily give your IT & OT engineers access to this environment to verify their own changes